The temperature code, represented like a T Code, establishes the maximum surface area temperature that an item will likely not exceed below specified ambient temperatures. This data is significant to prevent the ignition of hazardous gases or dusts as a result of connection with very hot surfaces.

And indeed, I’m just usually astounded in regards to the extraordinary matters served by you. Some four points on this webpage are undeniably the simplest I’ve experienced.

The size of the processing or storage unit, relief sizes, and ventilation are also crucial issues. By analyzing these parameters, operators can utilize diagram methods personalized for their certain facility specifications.

A small-scale radiopharmacy is often a facility where the small-scale preparation of radiopharmaceuticals is completed in accordance with countrywide regulations.

The intake of fresh air is split by the overall air change in the room and multiplied by one hundred to acquire the p.c contemporary air intake on Every single cycle because of the HVAC method in all the individual rooms.

(a) To get to the B, C, and D air grades, the amount of air changes should be associated with the scale in the room as well as equipment and personnel current during the room. The air program really should be furnished with proper filters such as HEPA for grades A, B, and C.

Connect the print outs, unique and photocopy provided by the external company of particle type of clean room with the First phase of contaminated area until recovery.

The enclosure also helps prevent the ignition of the explosive gasoline or vapor surrounding it. This kind of security operates at an exterior temperature that ensures the surrounding explosive ambiance will not be ignited.

Validation activities needs to be prepared in the validation system, in an orderly fashion. As an example, procedure validation should be done following the various output and good quality control read more equipment happen to be experienced, and not vice versa. In addition, validation routines need to be regarded as an integral A part of the quality assurance process, and should So be documented so as to guarantee the required traceability.

As soon as Original certification is complete, it can be crucial to consistently recertify to ensure that your cleanroom carries on to function since it did when it was crafted.

In the event that a monograph for the intended RP will not be posted, or just in case the monograph exists but for any explanations it can be desired to use a unique approach, its suitability need to be assessed and shown through a validation technique. Guidelines for validation of analytical procedures have already been produced by ICH (ICH guideline Q2(R1) Validation of analytical technique: text and methodology), which offer general information and facts read more and direction concerning the parameters to become examined (e.g. accuracy, precision, linearity, etcetera.), how to check them and when; For illustration, the above recommendations condition the willpower of repeatability need to be done just after no less than 9 analyses, masking the desired range of the procedure, etc.

3) decay / Restoration check, which is meant to ascertain time necessary to Get well the desired class right after e.g. HVAC is intentionally switched off for a defined time.

The conversion rate employed for this equation was obtained using the Currency Layer API (currencylayer.com). The conversion fee that your charge card provider uses may be distinctive. Shut

This kind of validation also requires the planning of a protocol, the reporting of the final results of the information critique, a summary and a advice.

Edward Furlong Then & Now!

Edward Furlong Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Elin Nordegren Then & Now!

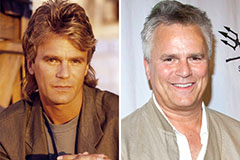

Elin Nordegren Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!